7 Comments

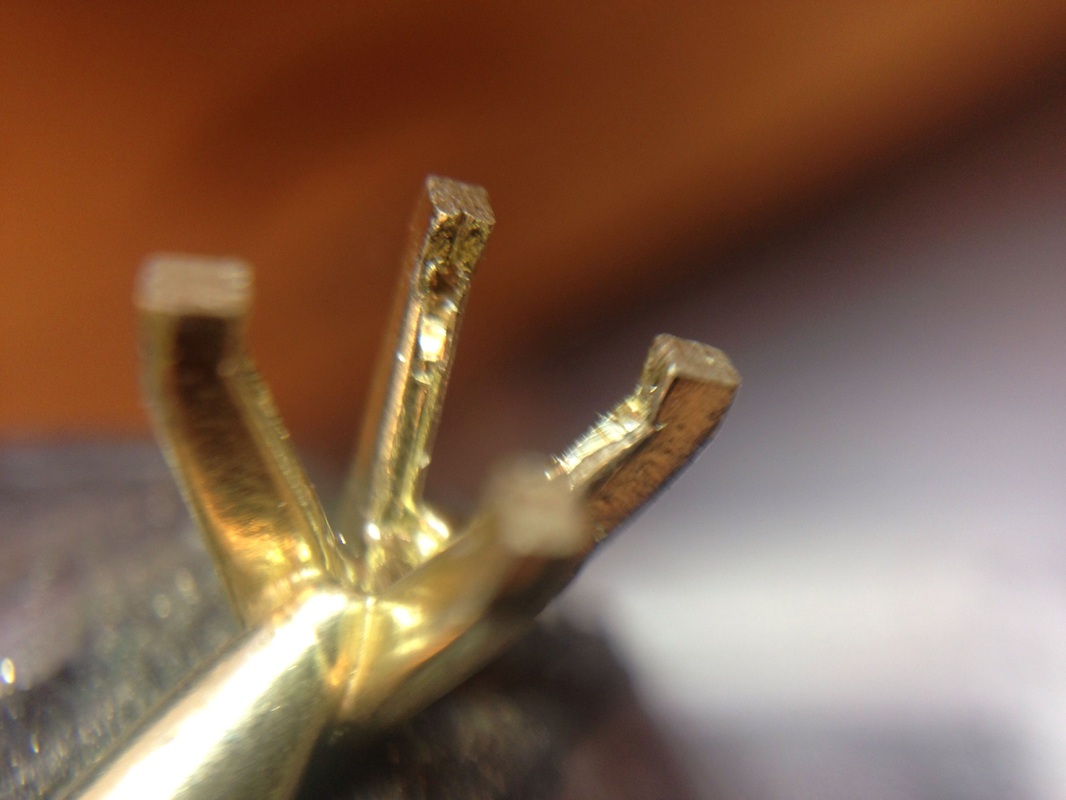

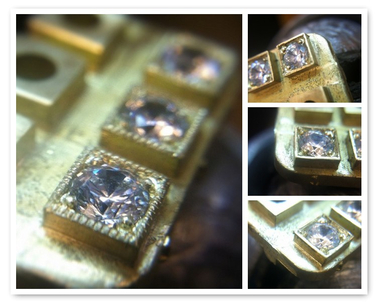

String polishing (thrumming) and final polishing to get the ring all gleaming! Anxiously awaiting the stone setting part, we were informed that we would not be setting at this point in time. Huh? That is like saying you can have cake but not the frosting!! Not. Fair. Groan. I never really have been a fan of prong settings. I now have a new appreciation for them. Especially hand fabricated ones. I find myself looking for new ways to incorporate prongs into my own designs. I think this could be an interesting adventure, Mr. Prong. You and I could become friends. Let's see where this journey takes us...

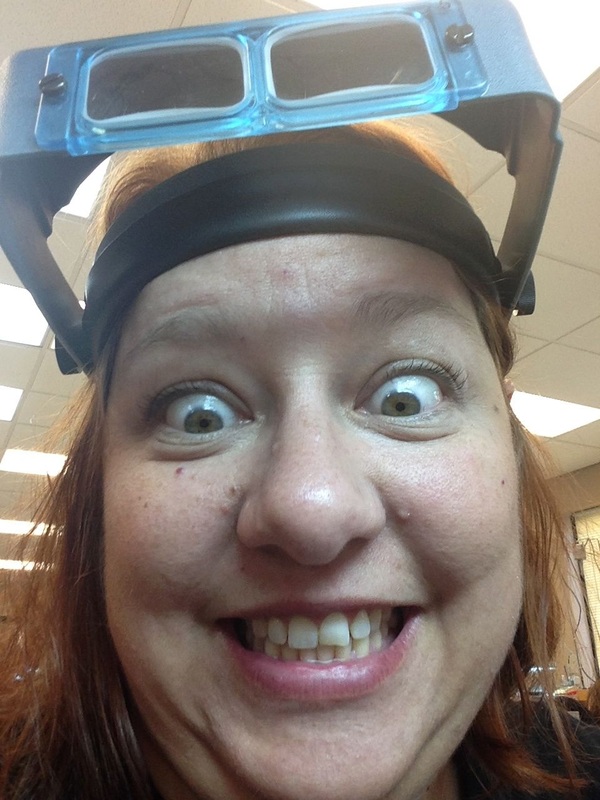

New grill selfie :) New grill selfie :) Week three, you kicked my ass. Woah. That was a rough road we traveled this week. Tears were shed, tantrums were thrown, frustrations took over. But we all made it through the battle and all are better jewelers for it. It is amazing what some of the students who have never picked up a saw frame or even a file can do after just three weeks. It's really incredible and wonderful to experience. Blaine is our Miyagi, our Mickey or our Morpheus. The confidence gained through the program is very empowering. Then he gave us a test... Well, you have to gauge progress some how, don't you? Oh deer-in-the-headlights.

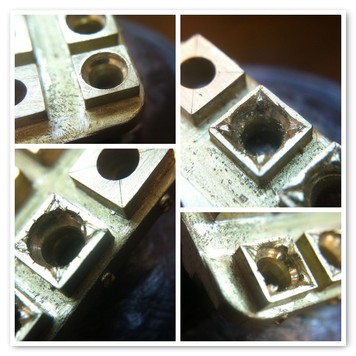

Bezel setting came in between bead setting styles. This technique is explained in great detail on Blaine's DVDs. I learned a lot of my stone setting from these DVDs. They are a very clear and descriptive way to learn bezel setting and flush setting. Learning in class was similar to the video but on steroids. Blaine teaches this in the Stone Setting Comprehensive week long class.

The week is rolling along with it's own set of troubles and then it happenened. We were surprised with a test. But not on what we have been working on all week but something we learned in week two. That was a thousand years ago!! The pressure! We were challenged with replacing a head on a solitaire ring and resetting the stone. Ok, breathe. Just unsolder and put it back together with the new one. Well, this ring is not soldered, it's laser welded and we have to cut it out. Now it got interesting. We weren't supposed to ask questions or share info with each other. I struggled through but remembered to just step back and examine what is at hand. With some brief calming exercises, I tackled the task successfully in the end. Whew! With that behind us we dove into chain repair, a non-stressful repeat of the solitaire exercise, and a little sneak peek at ingot making closed out the week. I know I was ready for the weekend. Week three, you were quite the evil little beast but I know I am better for having gone through you. Margarita time! Off to celebrate my beautiful little girl, Ruby, turning 9. Wow. How does that happen?

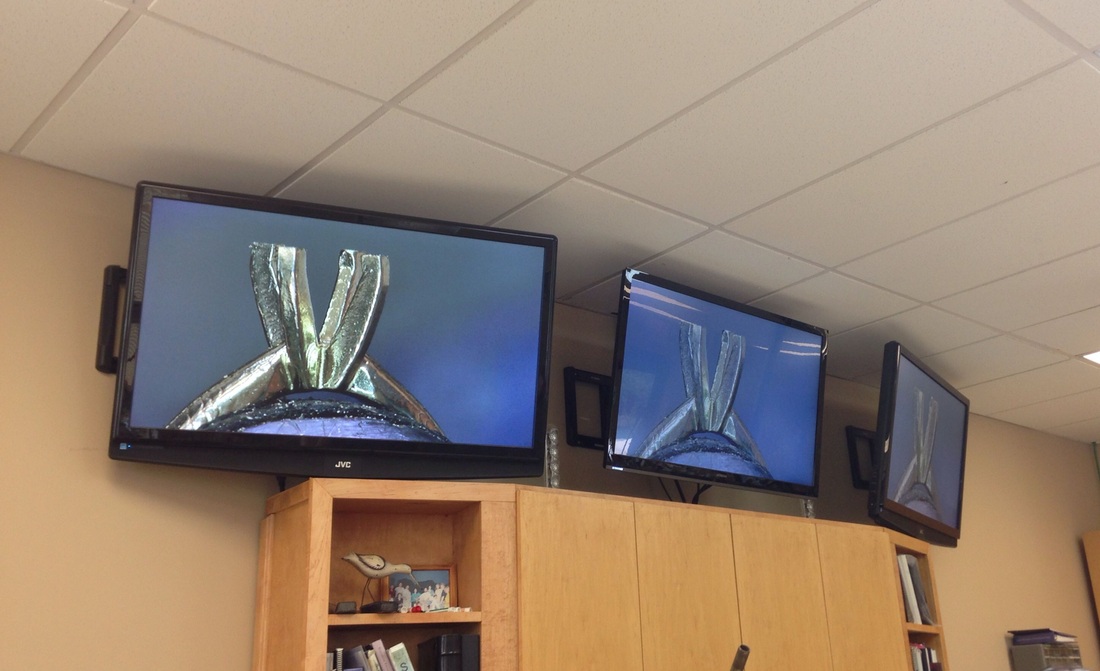

Moving quickly along to solitaire prong setting, Blaine directed us through bur control, angle alignment, vector tightening and the finer details that separate the average goldsmiths from the great goldsmiths. Tiny adjustments can make a world of difference. It is in the details, but the details don't really take that long. They can make a huge impact visually. I received a package of my work back this weekend from a gallery that unfortunately closed it's doors. So many things I missed or just glazed over. Not that any of it was horrible, just not what I want to pass as ok anymore. Oh the humanity!!! Naw, now I can see the little things that can make a difference in the overall appearance. Next week starts bead setting!! I've never done it before. This should be an interesting ride...Hang on! It's gonna get bumpy!

Fire! Max turning 10. Fire! Max turning 10. FIRE!! Yo, yo yo! Yes, we finally got to play with fire. The basics of firecoating, flux and soldering all were incorporated into practical use by teaching ring sizing and assembly of heads to shanks. A refresher in flame types was a good reminder as I often run my flame way too hot. Hence, the melting queen. Blaine uses Hoover and Strong's flux and it is da' BOMB! I have been suffering through with Handy Flux and Batterns for years. Why? Again. Why?? This flux actually REMOVES oxidides from the surface when heated. Never going back. Nu-uh. Can't make me. I have sized rings before but have a slight phobia as my first sizing I ever did, didn't go so well...That's another story for another day but it kind of shied me away from sizing for a decade. Sizing techniques taught this week really made sense and had a certain logic to them that will apply across the board to many styles of rings. Some solitaire assembly, three stone an shank assembly rounded out the fire section of week two. Blaine's ability to explain the process in a humorous and witty manner has made the days fly by these past two weeks. Looking forward to stone setting starting tomorrow!  Road Trip pit stop! Road Trip pit stop! Several years ago I heard of a school for jewelers called New Approach School for Jewelers. I knew a few goldsmiths that had gone through some of the classes and had spoken highly of the school. I had always dreamed of an opportunity to study in an intensive program really learning all the things I never was taught properly or was self taught half-assed. Well, the planets aligned in my favor or maybe I willed it to happen, either way, here I am in Middle Tennessee studying under Blaine Lewis at the New Approach School for Jewelers. Luckily, my little family was ready for a change, a new adventure. We had lived in Oregon for 20 years and loved every minute of it. (Well, most of every minute...) We recently moved to Portland, Oregon in 2012 and found we were all having a hard time fitting in. There were elements we loved but many we found not working for us. After a little re-con trip in June to Nashville, we packed our bags and headed to Tennessee! 2300 or so miles later, we landed and settled in to a town 25 minutes south of Nashville called Franklin. After unpacking the neccesities and getting the kids started in their new school, my new jewelry adventure began! The program is 12 weeks long and intensive. 9+ hour days and a ton of material is covered daily. Some people are starting having no experience at all, some with a little, and then there is me with 20+ years of mismash experience and learning that has led to bad habits and work that could be at a higher level than it currently is residing. I propose (insert attempt) to chronicle the program week by week sharing my thoughts, fears, and progress as I climb my way through the Graduate Bench Jewelers Program. I hope you will take a peek over my shoulder and share my adventure at the bench. Edit: A lack of internet for three and a half weeks, I am posting my first few posts this week to catch up. Recently I participated in the Chicago Gift Show in the Beckman's Handmade section of the show. This was my 5th consecutive time attending as an exhibitor. This show has always been a good show for my line and gives me a chance to see family and friends. And eat Chicago style pizza! My booth has evolved a bit from my first time attending but is still in constant flux. Chicago has hard walls (versus a pipe with drapes as the dividers) and can make things so much easier. A lot goes into creating this environment but I always receive compliments on the end result.

|

Renee FordMetalsmithing maven and mind behind Renee Ford Metals. I make the plain look interesting with fire, hammers & cool tools. Archives

February 2024

Categories

All

|

All jewelry is handmade in Nashville, Tennessee. I use recycled, responsibly sourced metals + gemstones. All designs + images are property of

Renee Busdiecker and Renee Ford Metals 2023

Renee Busdiecker and Renee Ford Metals 2023